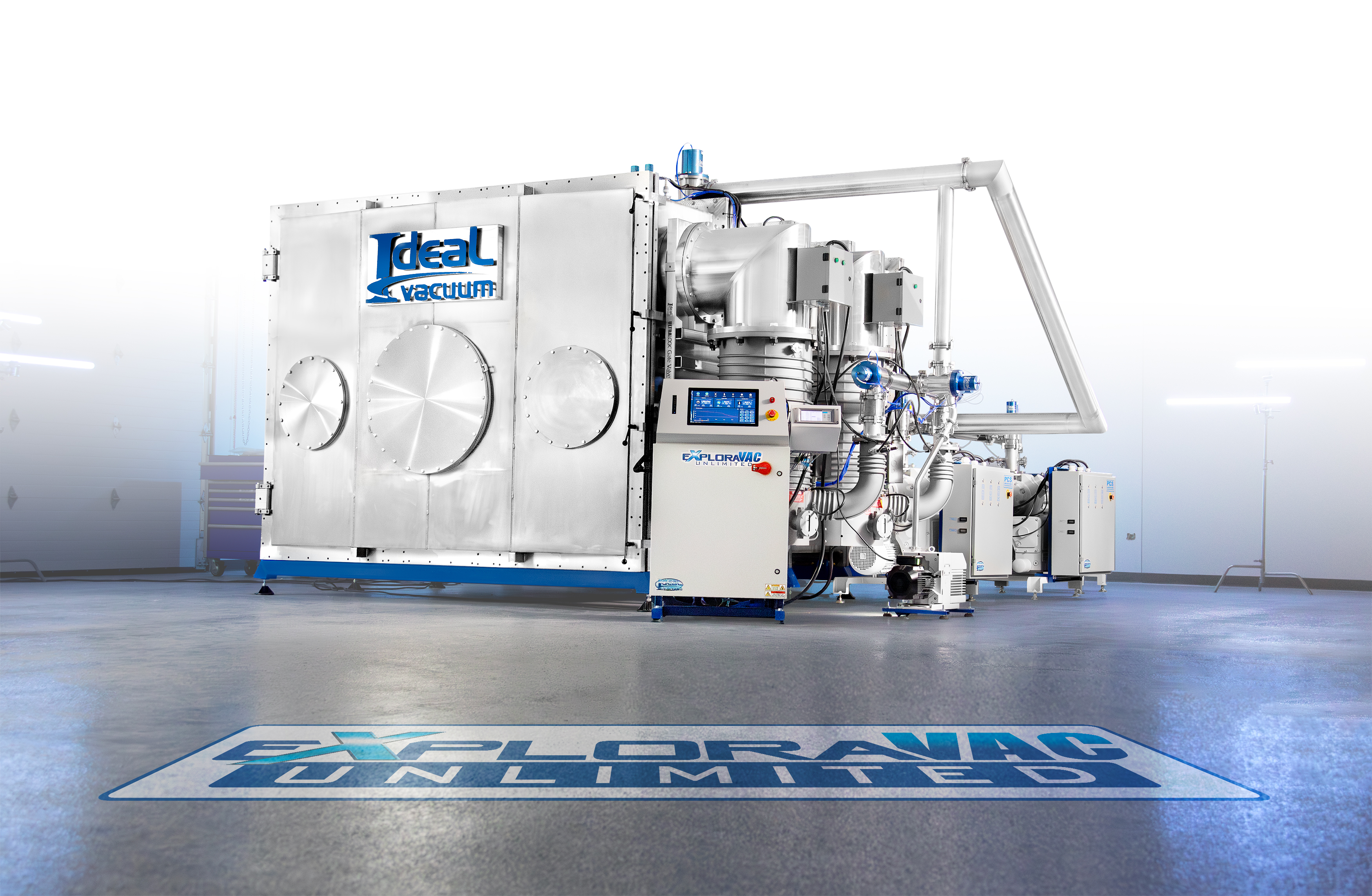

At Ideal Vacuum, we custom-build each of our

ExploraVAC™ Unlimited turn-key thermal high vacuum test chambers, they are delivered ready to run and designed to surpass our customers’ needs. This basic listing is for an

ExploraVAC™ Unlimited system composed of a single sectional chamber with internal dimensions of 3x3x3 ft, having a 27 cubic feet volume, being constructed of 304L stainless-steel, and based on our expandable sectional chamber design with hinged access doors including multiple large ISO ports for easy mounting of feedthroughs, windows, and instrumentation. It includes full-pullout platen which is liquid nitrogen cooled (LN2) down to -170 °C, resistive heating up to 375 °C, and having a thermal ramp rate ranging from 7 - 10 °C/min for fast cycling. The selected high-vacuum pumping system includes clean-dry vacuum pumps, Edwards nXR60i roughing pump and Edwards nEXT1230 turbo high-vacuum pump, which pull the system down to ultimate pressure of 5x10-7 Torr in less than 2 hours. This preconfigured

ExploraVAC™ Unlimited system is a perfect choice for space simulation testing of satellite batteries, solar panels, instrumentation, or complete small satellite assemblies.

Engineered Without Limits – Watch the ExploraVAC Trailer

Spacecraft designed for Lunar or Martian landings must endure some of the harshest environmental conditions in the solar system. On the Moon, surface temperatures swing from about –170 °C during the night to +120 °C in direct sunlight, while Mars ranges from roughly –125 °C at the poles to +20 °C at the equator. Atmospheric pressure varies dramatically: the Moon offers a near hard vacuum, while Mars has a thin CO2 atmosphere at 3–10 Torr (less than 1% of Earth’s sea-level pressure). Both environments bombard hardware with ultraviolet radiation due to the lack of protective atmospheres, and electrostatic charging causes abrasive dust to cling stubbornly to surfaces. Lunar regolith contains extremely fine, sharp-edged particles, many less than 20 microns in size, capable of infiltrating seals and mechanisms, while Martian dust storms can loft particles into suspension, coating sensors and optics. By reproducing these thermal extremes, pressure conditions, particle sizes, UV exposure, and electrostatic effects in an Earth-based lab, the

ExploraVAC™ Unlimited system ensures that spacecraft subsystems can be thoroughly tested against the realities of lunar and Martian operations.

The system is powered by the

ExploraVAC™ Unlimited Control Platform with

AutoExplor™ software on a side mounted control console, has a conveniently angled front panel full touchscreen interface with manual emergency-off switches, supports controlled ascent and descent in pressure for sensitive components, rapid decompression profiles, altitude flight simulations, and much more. Our

AutoExplor™ software package goes beyond expectations, in fact our customers love how easy it is to use, and they learn to drive the

ExploraVAC™ Unlimited system within minutes. It’s such a strong selling point that customers want to buy our systems just to have

AutoExplor™ . In addition, the side mounted control console has a PLC which manages system functions including pump and valve sequencing for efficient pump down cycles and safety interlocks for preventing equipment damage. Ideal Vacuum has our UL 508A panel shop certification that qualifies us as a industrial control panel manufacturer to design, build, and label panels in compliance with UL safety standards.

Our

ExploraVAC™ Unlimited systems are designed for safety & convenience with standard features including integrated inductive door switch for safety lockouts, external light override switch on control console, LED halo view windows for chamber illumination, and additional welded threaded studs for custom mounting (6 per chamber section).

ExploraVAC™ Unlimited systems for key environmental conditions for Lunar & Mars landing mission testing

- Vacuum and low-pressure atmosphere – Simulating near-vacuum conditions on the Moon and the thin CO2-rich atmosphere on Mars

- Dust & regolith exposure – abrasive, fine-grained simulants to test seal, bearing, and mechanism durability

- Electrostatic charging – dust particles carrying charge that adhere to surfaces and interfere with electronics

- Thermal extremes & cycling – wide temperature swings (e.g., –150 °C nights to +120 °C days on the Moon)

- Solar radiation & UV exposure – effects of unfiltered sunlight and UV on materials and coatings

- Bead-Blasting particle impacts – simulating landing plume effects that loft and accelerate dust against hardware

- Outgassing & contamination – monitoring volatile release from materials that could redeposit on optics or sensors

- Vibration-induced dust infiltration – particle intrusion into joints, gears, and electronic housings under mechanical stress

- Seal & filter performance – verifying filtration systems that protect pumps, life-support systems, and enclosures

- Component longevity under dust loading – measuring wear, erosion, and performance degradation over repeated cycles

With the

ExploraVAC™ Unlimited system for Lunar or Martian landing environmental testing simulation, you’re not just buying a chamber—you’re deploying a future-proof, fully supported space simulation platform. From research labs to flight-hardware qualification, this system delivers the performance and flexibility that keep programs on schedule. It’s truly the best of the best, built to help you achieve mission success. ExploraVAC Unlimited systems are engineered for both mission-critical environmental simulation and high-performance vacuum processes. Whether you're qualifying flight hardware through altitude and thermal cycling, or running precision-controlled bakeouts, degassing, or thermal processing routines, these systems deliver the flexibility and performance needed to do it all. Unlike bulky, single-piece chambers, the

ExploraVAC™ Unlimited system features a sectional architecture so large systems ship in manageable sections and assemble quickly at your site, reducing freight cost and installation complexity. Each section is engineered for precise alignment and sealed integrity, with front and rear doors, multiple viewports, and broad compatibility with integrated subsystems—so your layout matches your workflow.

Optional Space Landing Features for Ruggedized Dust & Regolith Simulation Systems

- Custom dust injection systems – controlled delivery of Lunar and Mars regolith simulants to replicate plume-driven particle impacts

- Advanced multi-stage filtration – replaceable foreline filters, cyclone separators, and HEPA-grade traps to protect pumps and sensors from abrasive dust

- Electrostatic charging & neutralization modules – simulate dust adhesion due to static buildup and test ESD mitigation strategies

- UV Illumination arrays – replicate solar UV radiation for evaluating coatings, optics, and surface degradation

- Thermal cycling packages – platen or shroud-based systems to reproduce extreme Lunar & Martian day/night temperature swings (–170 °C to +120 °C)

- Dust recovery & recycling systems – collection bins or recovery hoppers for regolith simulants, reducing consumable costs

- High-Speed particle blasting module – simulate regolith lofted and accelerated by rocket plumes during landing

- Optical & Spectroscopy ports – windows and feedthroughs for high-resolution imaging or spectroscopy during dust exposure tests

- Automated dust monitoring sensors – real-time particle counters or laser scattering instruments for measuring density and distribution inside the chamber

- Custom fixtures & mounts – specialized hardware for holding lander mechanisms, seals, electronics, or optics under dust-laden conditions

- IR lamps to deliver high power thermal flux conditioning

- Thermal Conditioning Units (TCUs) with wide temperature range and uniformity

- Full-pullout platens which Unistat chiller offering 9 kw of cooling and 12 kW of heating power

- Precise temperature control between -80 °C to +200 °C

- Residual Gas Analyzer (RGA) for in-situ gas analysis in vacuum systems

About Space Simulation:

The conditions felt in space are extreme. Satellites, CubeSats, and spacecraft experience constant high vacuum and large temperatures swings during the day-night cycle as they pass into the suns unfiltered rays and then into the earth’s cold shadow. For example, an object in low earth orbit without temperature regulation mechanisms may reach -170 °C in the night and 123 °C in the day. Due to the high cost of launching an object into space, it is crucial, and often mandatory, to rigorously test all individual components and the entire assembled device before deployment.

Additional Applications for Lunar & Martian Landing Condition Simulation:

- Rover Mobility Systems – testing wheel assemblies, suspension systems, and drive mechanisms in dust-laden vacuum environments

- Optical Systems & Cameras – evaluating how dust accumulation, UV exposure, and thermal swings affect lenses, sensors, and optical coatings

- Seals, Bearings & Mechanisms – verifying long-term durability of moving parts exposed to fine abrasive regolith particles

- Filtration & Dust Mitigation Technologies – validating air filters, electrostatic dust shields, and cleaning devices under realistic conditions

- Spacesuit & Visor Testing – studying abrasion, coating durability, and dust adhesion on suit fabrics, visors, and life-support interfaces

- Solar Panel & Power System Testing – analyzing efficiency losses due to dust deposition and thermal cycling on photovoltaic arrays

- Habitat & Airlock Component Development – ensuring doors, seals, and docking systems remain operable under regolith exposure

- Material & Coating Development – testing protective coatings, polymers, and composites against UV radiation and abrasive dust wear

- Planetary Protection & Contamination Studies – studying how dust transport could affect scientific instruments or contaminate sensitive surfaces

- Defense & Industrial Applications – ruggedization testing for vehicles, drones, or electronics designed for desert or dust-prone environments on Earth