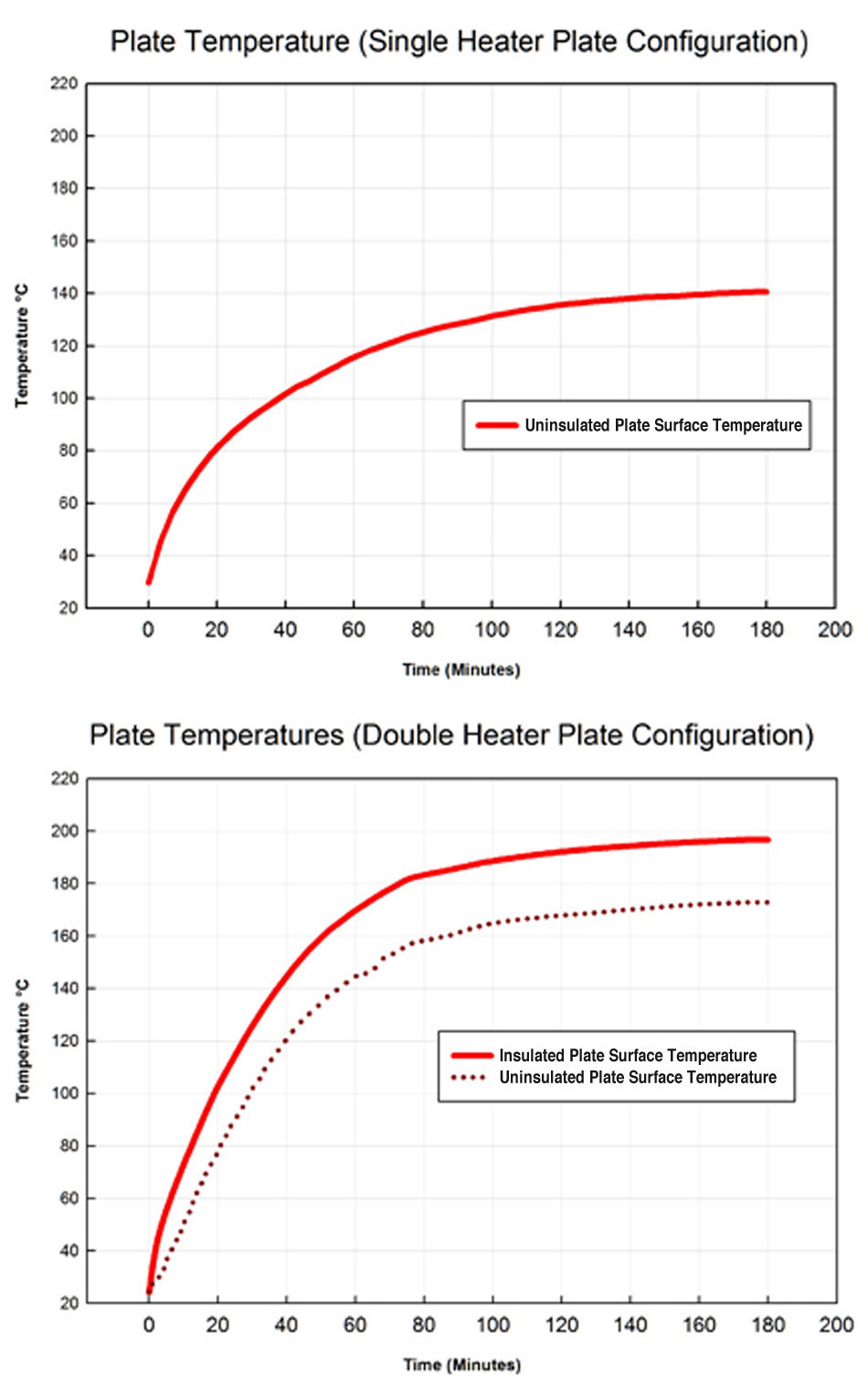

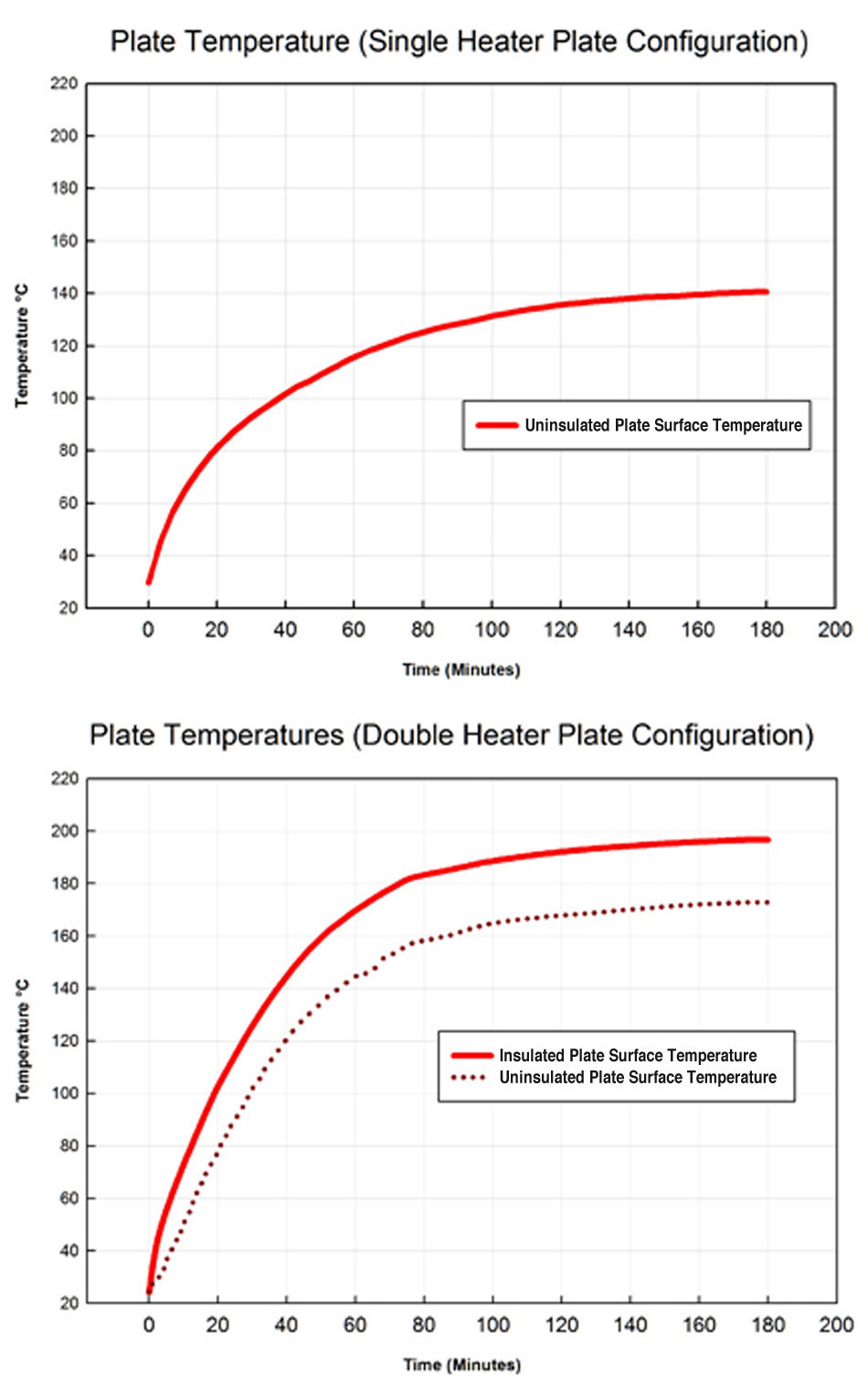

These Ideal Vacuum Cube 6x12 inch heater plates are designed to fit our 6x6x12 vacuum cubes (each cube requires 6 plates) and will safely provide up to 140°C of uniformly distributed heat to the vacuum side of the plate surface, through a 120VAC 360W heating element. These vacuum thermal test fixtures expand the capabilities of our Ideal Vacuum Cubes whereby they can be used as Thermal Vacuum Chambers (TVC) or Thermal Shock Vacuum Chambers (TSVC). Applications include thermal stability testing, surface coating and implantation, and damage testing under thermal load.

This heater plate has an integrated Type-K thermocouple, and works directly with our

single zone PID Plug & Play Heater Control Systems, which are designed to accurately measure and control the temperature of our Cube heater plates. When a single Cube heater plate is used, and once the system has reached thermal equilibrium, the rest of the chamber will be approximately 10°C less than the heated plate itself. Multiple heater plates may be used (up to the heater control system's maximum power load) to help eliminate this temperature differential.

Please note that the maximum allowable temperature using Viton O-rings is 150°C. If your Cube chamber application requires higher temperatures and multiple heating plates, you will need our

high temperature vacuum Cube hardware kit with Kalrez O-rings, which will increase the maximum safe operating temperature to 275°C. Please contact customer service online or at (505) 872-0037 to order a high temperature Cube kit.

Please note that ramp-up time is dependent upon the heater control system, number of heater plates, ambient operating conditions, and whether the vacuum cube is insulated. Importantly, temperature gradients due to conductive losses through the heater plate edges are kept to a minimum with integrated, machined stand-offs that minimize the contact surface between the plate and the Vacuum Cube frame. An aluminum anodized shield on the air side of the heater plate helps control convective losses due to ambient conditions (and helps protect users from direct contact with the heated plate).

As the plots above demonstrate, maximum plate temperatures will depend on number of heater plates used, ambient operating conditions, and whether or not the vacuum cube is insulated.

These Vacuum Cube plates are CNC milled from a single block of lightweight 6061-T6 Aluminum Alloy and are designed to consume minimal volume inside our 6x6x6 Ideal Vacuum Cube while expanding its capabilities.

Thermal Vacuum Chambers are often used to replicate or simulate the extreme conditions of outer space and are frequently employed in the testing of spacecraft and aerospace parts or components under a simulated space environment, and control outgassing characteristics for a giving process.

The vacuum chamber side (back) of these heater plates have a threaded optics table breadboard pattern, tapped 1/4-20 drilled on 1 inch center, for mounting opto-mechanical vacuum compatible optical posts, mirror mounts, lenses, polarizers, and other optical and test hardware components. These plates use Viton o-rings, are made of 6061-T6 aluminum alloy with a red powder coated outside finish, and can be mounted in any orientation. This is the sale of an Ideal Vacuum Cube heater plate only (other plates, frame, and hardware are required and sold separately).

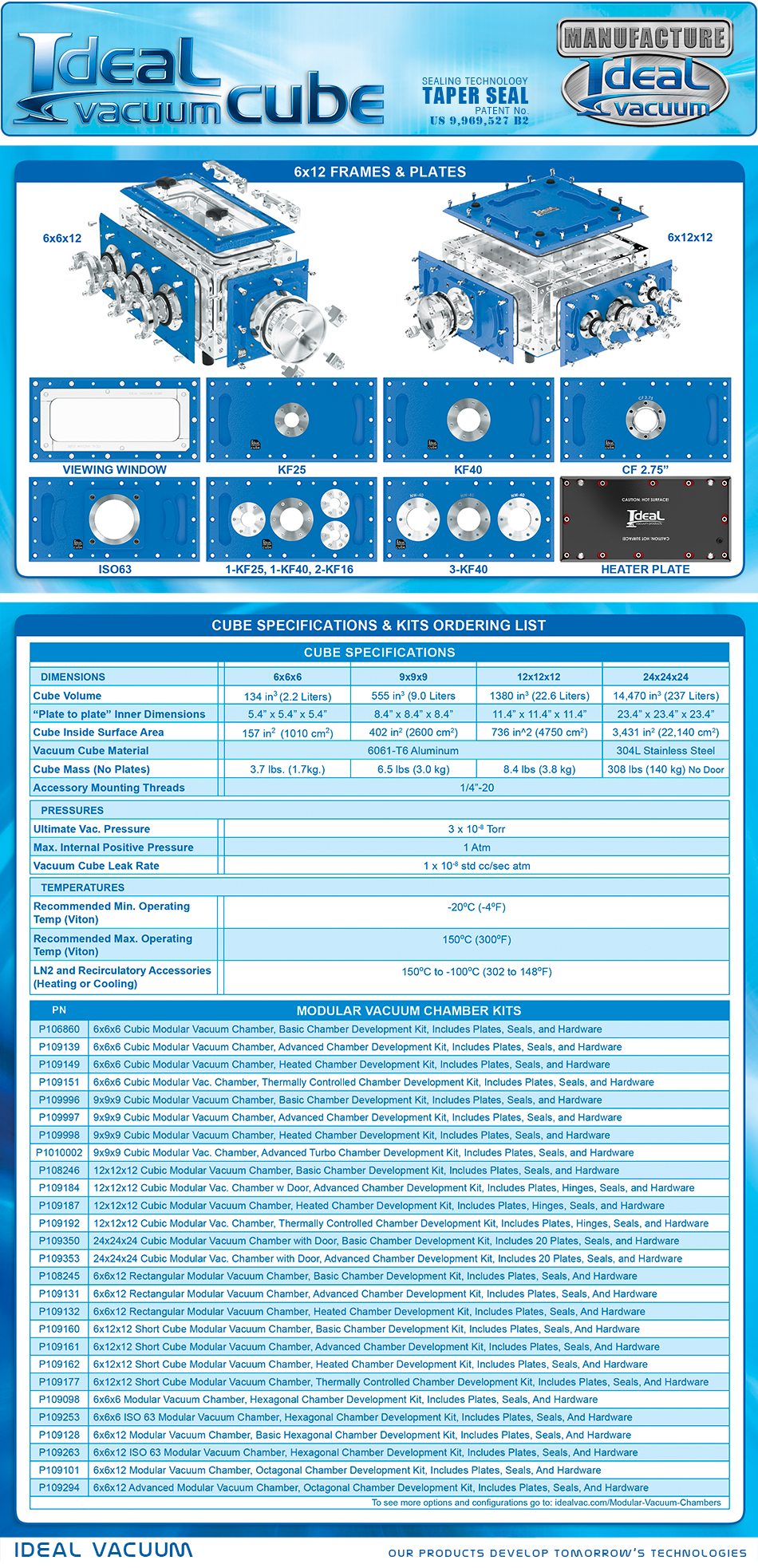

Ideal Vacuum Cube Introduction

Our Ideal Vacuum Cube is a modular high-vacuum chamber system, conceived to enable creativity and design flexibility in vacuum chamber system construction. Cubes can be stacked together into various shapes and configurations, with interchangeable plates offering a variety of features for connections, windows, and feedthroughs. Plates include 1/4"-20 mounting threads on a standard 1" optical pattern for easy connection of hinges, posts, mounts, lenses, polarizers, and other accessories.

Durability and Versatility

The large inner dimensions and open design of Ideal Vacuum Cubes makes them perfect for many vacuum chamber applications and experiments. Vacuum Cubes are constructed of lightweight 6061-T6 aluminum alloy, allowing them to be easily transported around the lab and mounted on optical tables (unlike heavy stainless steel vacuum chambers). A patented seal protective design, stainless steel thread inserts, and powder-coated outside plate finish help make the Vacuum Cube a durable tool for even the most demanding use.

Technical Details

Patented Chamber System

Our Ideal Vacuum Cubes have a patented design which features our Taper-Seal technology. Unlike other vacuum flange designs, such as, Conflat CF, KF/NW, or ISO-LF (large flange), which can be easily damaged when set on work surfaces, our Taper-Seal design protects critical sealing edges and o-rings from contact which can cause damage or contamination.

Innovative Chamber Building Blocks

Ideal Vacuum Cubes can easily be stacked together to build a complex, yet lightweight vacuum system (see graphic below). The outer edges of each vacuum cube feature hardware mounting sockets for easy cube-to-cube connections. A cube coupling kit includes the hardware needed to connect two cubes together. This allows scientists to creatively construct long or odd-shaped vacuum systems in a laboratory.

Configurable Plates and Accessories

The Vacuum Cube can be configured with a wide variety of plates and windows with many options. A Vacuum Cube can be fitted feedthroughs for electrical power, thermocouple temperature measurements, optical lasers light or imaging detectors, gas supply, or fluid flow for heat/cooling recirculation lines. Compatible standard flange styles include KF-16, KF-25, KF-40, KF-50, ISO-63, along with conflat CF 2.75, CF 3.375, and CF 4.5 inch flanged ports. Viewing windows are also available, and custom plates can be manufactured on request. An optional hinge kit can be ordered to convert any plate into an operable door.

Applications for Ideal Vacuum Cubes

Our Ideal Vacuum Cubes are designed to implement well into optics laboratories for quick installation in laser research applications. The modular design of our Ideal Vacuum Cubes make them suitable for many vacuum chamber applications:

- Laser Spectroscopy

- Cavity Ring Down Spectroscopy (CRDS)

- Vacuum Ultraviolet (VUV) Devices and Experiments

- Thermal Vacuum Testing

- Altitude Testing

- Vacuum Degassing Chamber

- High Power and Ultra Short Pulsed Lasers Research and Development

- Ion Acceleration

- RGA (Residual Gas Analyzers)

- Helium Leak Testing of Hermetic Sealed Devices With Welded In Helium Atmosphere

- Leak Detection Of Pharma Packaging

- Spectroscopy

- Molecular Ion Trap

- Cryostat Vacuum Chamber

- Beamlines

Vacuum Cube Pumping Performance

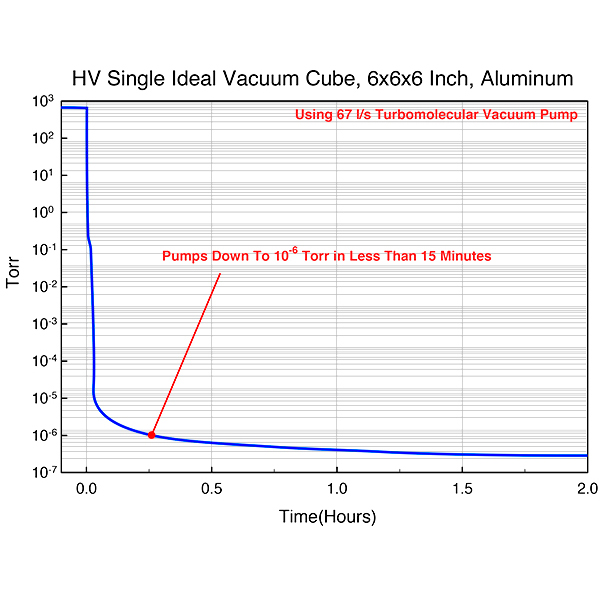

The pump down curves for several Ideal Vacuum Cube configurations are shown in the graphs below. A single 6x6x6 inch Cube can be pumped from atmosphere to 1x10

-5 Torr in 2.5 minutes and below 1x10

-6 Torr in around 15 minutes.

(

view curves graphic 1)

This was accomplished using a 68 liters/second turbomolecular pump backed by a 110 liters/minute (3.3 cfm) dry scroll vacuum pump.

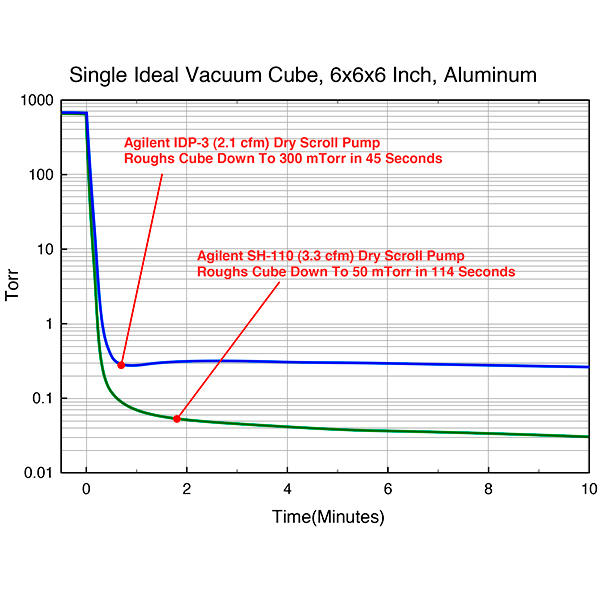

We have also provided roughing pump down curves for popular Agilent Varian IDP-3 and SH-110 dry scroll pumps. The 6x6x6 Cube reaches base pressure of 300 mTorr for the IDP-3 (2.1 cfm) in less than 1 minute of pumping, and 50 mTorr for Agilent Varian SH-110 (3.3 cfm) in around 2 minutes.

(

view curves graphic 2)

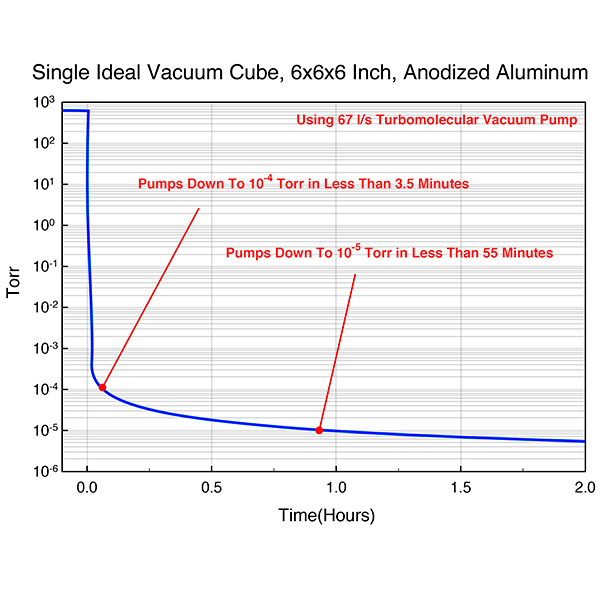

On special request we can offer fully anodized plates to help with absorption of scattered light in laser research and optical applications. Anodized components do not pump down as fast as bare aluminum metal surfaces.

(

view curves graphic 3)

A single 6x6x6 with anodized plates required 1 hour of pumping to reach 1x10

-5 Torr.