|

| Viewport, Fused Silica, Zero Length 2.75 inch Conflat Flange (CF-2.75 in.), DUV Grade, AR Coating, 1.4" Viewport Diameter, 304 SS |

|

|

|

|

|

Viewport, Fused Silica, Zero Length 2.75 inch Conflat Flange (CF-2.75 in.), DUV Grade, AR Coating, 1.4" Viewport Diameter, 304 SS

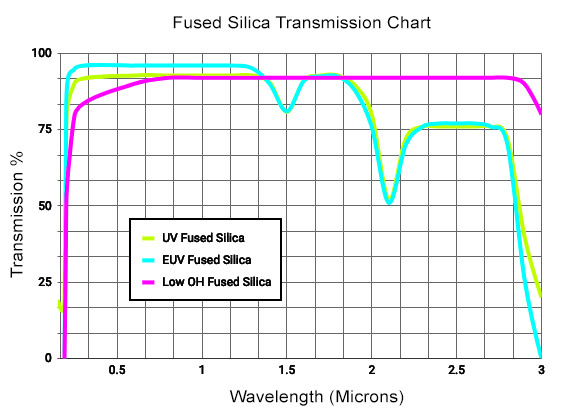

DUV-grade fused silica for applications requiring transmission deep into the ultraviolet spectrum in addition to a low index of refraction for a given wavelength, excellent homogeneity, and low coefficient of thermal expansion. Unlike common glasses (Pyrex, borosilicate, soda-lime, etc.) fused silica contains no Na2O, CaO, or B2O3 and is composed exclusively of high-purity silica (SiO2) in amorphous (non-crystalline) form. It has a much higher working and melting temperature than other common optical glasses, and has exceptional optical, thermal, and mechanical properties.

Fused silica is highly resistance to thermal shock, and is an excellent material for applications requiring the utmost in dimensional stability over a large temperature range and steep thermo-temporal gradients. For comparison, INVAR (a nickel-iron alloy), which has the lowest thermal expansion among all metals and alloys near room temperature, has a mean coefficient of thermal expansion that is more than twice that of fused silica over a temperature range of 20°C to 100°C.

Fused Silica is an extremely inert glass and is compatible with the vast majority of chemicals used in the industry and in the laboratory. There are only a few uncommon materials that will attack it, including HF (hydrofluoric acid) and hot KOH (Potassium hydroxide). Although this substrate does not scratch easily, it should, like all fine optics, be handled with care. When handling optics, always wear soft, non-absorbent, lint-free gloves. Please observe the following procedure when cleaning these viewports:

• Always start by blowing off window first with clean, dry compressed air. This will remove any potentially hard, gritty dust that could cause scratching during cleaning.

• Always use a solvent-dampened swab to wipe clean a window, a dry swab can potentially scratch a window and in any event will leave more than it cleans if not damp.

• Excess solvent should be flung off by a flip of the wrist. If the swab is heavily soaked with solvent, the window will rapidly chill due to solvent evaporation; this will result in water condensation from the air. It may cause spotting or delays in cleaning. It is best to flip off the excess before touching the window with the swab. Alternatively, one can daub the swab on a piece of lint-free tissue to partially remove solvent.

• Compressed air in a can, if tipped upside down or violently shaken, will cause solvent to spray out with the air. No canned duster is perfect. Occasionally some solvent will contaminate the window. The best solution is to use a regulated supply of commercial dry compressed nitrogen gas from a welding gas supply company.

• Always handle the window with protected hands. Powder-free vinyl gloves work best; but, if touched with acetone they can dissolve and leave residue on the window. One should carefully avoid contacting the cleaning swab directly with the glove during the cleaning procedure.

|

|

|

|

|

|

| Product: |

Viewport, Fused Silica, Zero Length 2.75 inch Conflat Flange (CF-2.75 in.), DUV Grade, AR Coating, 1.4" Viewport Diameter, 304 SS |

| Condition: |

New |

| Warranty: |

Against Product Defect |

| Part Number: |

P1010666 |

| Price: |

$1,262.65 |

|

|

|

|